Product name:Robot welding machine

Category:Robot welding machine

Release time:2024-11-28

Number of views:84

Product Introduction

A large state-owned heavy equipment manufacturing enterprise, whose main products include lifting equipment, mining equipment, wind power equipment, marine equipment, rail transit, engineering machinery, etc. The introduction of Renxin robot programming free robot welding machines in production greatly reduces the labor intensity and operational difficulty of workers, and improves the efficiency of production management.

Case introduction

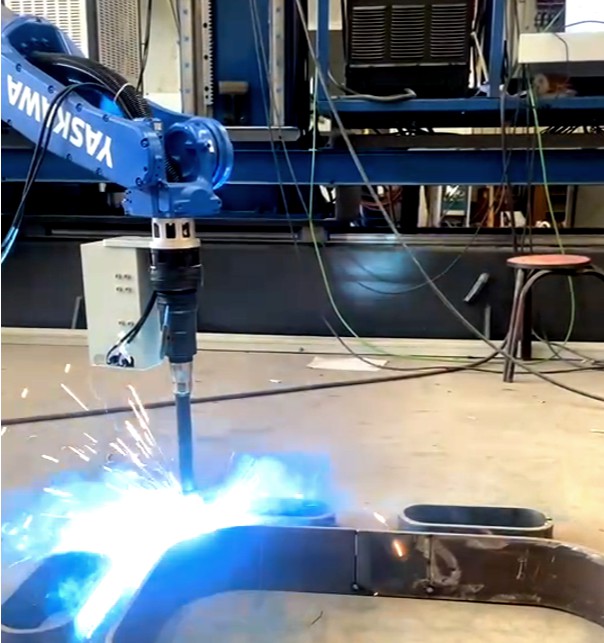

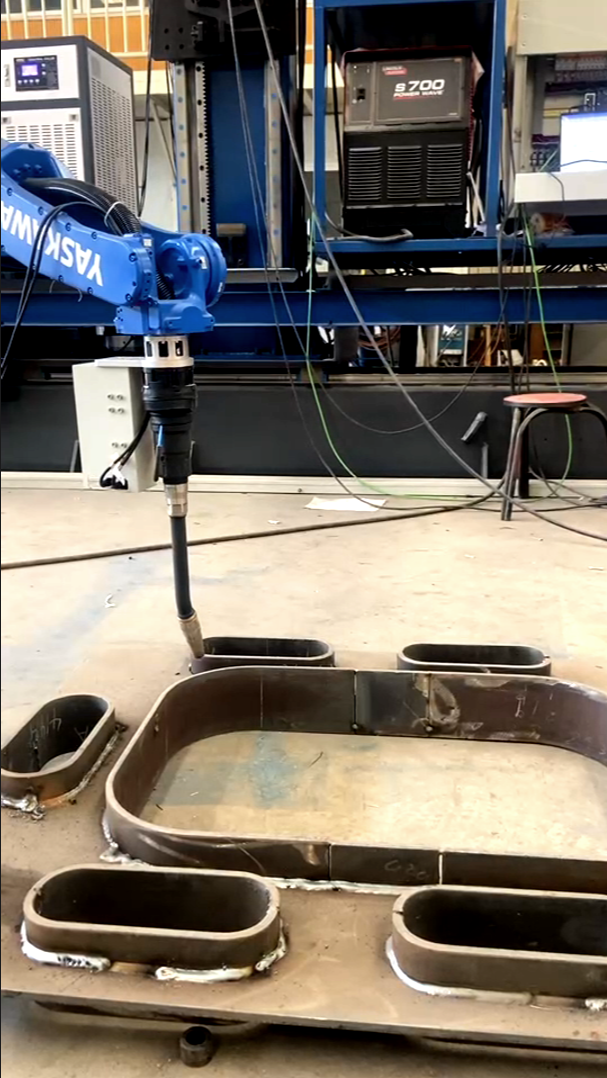

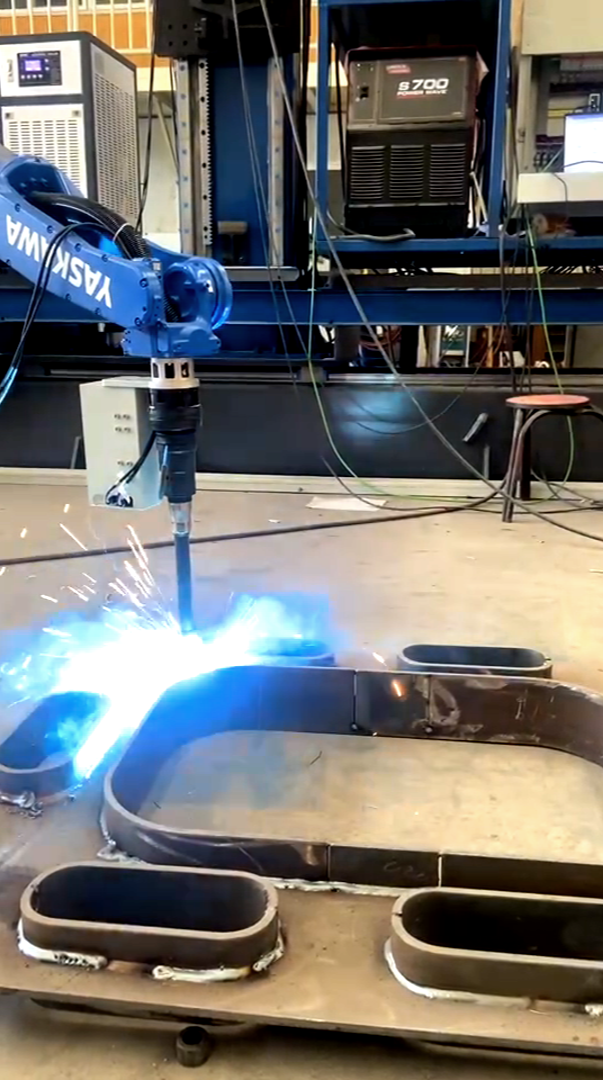

There are many types of workpieces for the main beam of cranes, which are composed of large rib plates, reinforcement rings, and walking coils. Traditional manual welding methods are inefficient, have long production cycles, and require high skills from workers, making them prone to errors and not ensuring complete welding quality.

In the original production process of the customer, the welding process of the large rib plate was manually operated, which resulted in high labor intensity and difficulty, posing safety hazards, and unstable welding quality, affecting product quality.

Solution

Based on the existing production process, product specifications, product drawings, and other requirements, customize the design of equipment structure and functions to meet actual production needs. The workstation consists of a set of inverted 6-axis welding robot system, a set of 2-axis mobile (X-axis walking and Z-axis lifting both use the external axis of the robot) inverted single robot cantilever slide system, a set of horizontal fixed workbench (provided by Party A, with a ground height of 200-400mm), a set of robot 3D vision scanning system, and a centralized welding smoke purification system.

Equipped with MES interface for equipment informatization and visualization, it can achieve interconnection and intercommunication between equipment and production management system, improving the efficiency and accuracy of production management.

We provide comprehensive service support including research, experimental verification, installation, debugging, and training to help customers better apply and operate our products.

Project results

The Renxin robot welding machine has been put into use, realizing the intelligent production of this production line:

1. Intelligent welding of large rib plates and other components has been achieved, greatly improving production efficiency and shortening production cycles.

2. Reduce the labor intensity and operational difficulty of workers, minimize safety hazards, and improve the stability of welding quality.

3. Realize the informatization and visualization functions of equipment, improve the efficiency and accuracy of production management.

4. Satisfied customer needs, achieved customized production of small batches and multiple varieties of products, and improved product competitiveness.

- Previous article:

- Next article:Robot welding machine